ARC Waste Tires Inc

Preserving our Earth one tire at a time

About

ARC Waste Tires Inc. was formed in late 2010 and represents the culmination of many years of research, analysis, planning, and negotiations. Through an exhaustive global search, the company has identified both a proven technology and a solvent capable provider.

ARC Tires currently employs a proven pyrolysis system which has been ongoing development for over 20 years and is currently employed in China, Taiwan, Malaysia, Thailand, India, France, Brazil, Hungary, Estonia, and Germany.

The only major competition is generally companies that resell old tires. It would be great to have partnerships to direct all scrap and used tires to our facilities.

There is a small market of cement kilms and some power plants for solid TDF (Tire Durative Fuel) direct burning of waste tires However, these plants have a problem with stack emissions and additional expenses such as scrubbers, which make these operations unsustainable.

There are also other small recycling facilities turning tire waste into usable products. These represent a small percentage of the total market and will not interfere with our tire supply chain for the pyrolysis plant.

The Company has obtained several supply chains throughout the nation and will easily be able to supply up to 150 tons of used waste tires per day. The waste tires will be supplied to the Company at little to zero cost.

For conservative purposes, the financial exposure of the waste tires is transferred at $10 per ton. The advantage to the Company is obvious; raw material is less than 3% of sales. This arrangement allows tire re-sellers to avoid the cost of depositing the 150 tons of tire/day into a landfill. The cost advantages are trucking the tires to the landfill as well as the tipping fees at the landfill. The arrangement is a win/win for both parties.

To capitalize on our system, it would be great to have a partnership with the city of Adalento. We are looking forwards to work with and fast track approvals of permits from Adalento for future supply chains.

Approvals

These are lab test reports for our pyrolysis system.

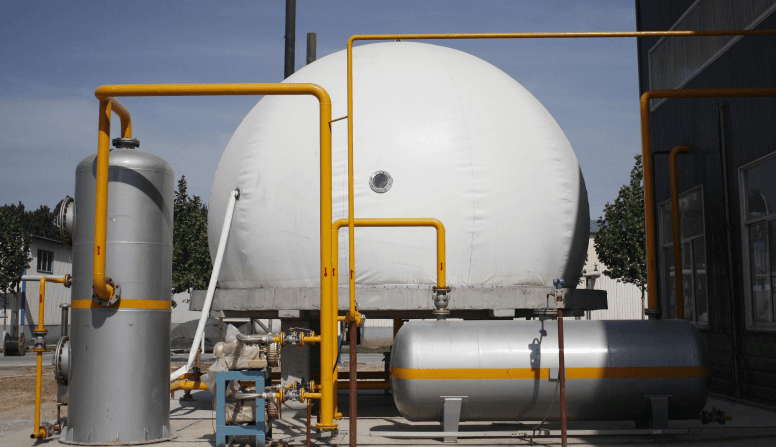

Pyrolysis Technology

Solid biomass can be liquified by pyrolysis, hydrothermal liquification or other thermo checmical technologies. Pyrolysis and gasification are related processes of heating with limited oxygen. Conditions for producing pyrolysis oil are more likely to include virtually no oxygen. Pyrolysis oil and other thermo chemically-derived biomass liquids can be used directly as fuel and also hold great promise as platform intermediates for production of high-value chemicals and materials.

In regards to the pyrolysis, the system processes tires primarily into three products; carbon black, fuel oil (as a gas), steel (the steel belt in the tire) and other hydrocarbon gases.

The carbon black, fuel oil, and steel can be sold at substantial profits. Remaining hydrocarbon gases and the fuel oil are used as power for the heat source used in the pyrolysis process, reducing production costs.

Our total system (single group of 10,000 tons/year, total of 5 groups) is capable of handling 150 tons of waste tires per day, producing 60 tons of fuel oil, 52.5 tons of carbon black, 22.5 tons of steel braid, and 15 tons of hydrocarbon gases

The Finished Products

45% of the system goes towards Fuel Oil. The oil product generated by the system can be marketed directly to industrial markets. The fuel oil has the chemical characteristics (heat value) to #2 Diesel Oil.

Approximately 35% is Carbon black. Carbon black is an essential ingredient in tires and other mechanical rubber goods. It improves product durability and overall performance. It is also used as a pigment in numerous printing inks, paints and plastics.

15% goes to Steel Braid. The steel content inside tires ranges from 10% to 15% of total tire weight. Steel braid is used widely in several industries in which you want to toughen appliances.

The last 5% goes to Hydrocarbon Gas, which are non-condensable gases recovered from the pyrolysis process, used as a fuel source for the process furnace to reduce operating costs.

The system is currently in its 7th generation of developed systems. It has evolved from a simple batch type system (generation 1) to the current generation version which is a continuously operated (24/7). The high output level of fuel oil is comparable to #2 low sulphur diesel oil. All 6 generations of the equipment are still in operation today and some are available for on-site visits.

The core system is designed and built by joint efforts between China and Germany. All additional equipment required for a complete plant is obtained through various domestic and foreign manufacturers.

The core system is designed and built by joint efforts between China and Germany. All additional equipment required for a complete plant is obtained through various domestic and foreign manufacturers.

Our advanced system uses a patent pending catalyst which is added to the tires before they enter the reactor, which is where the pyrolysis reaction occurs. The catalyst improves the efficiency of the pyrolysis, to maximize profits.

The complete pyrolysis system has been designed to meet various countries air emission standards. To meet various countries air emission requirements, SGS, an internationally recognized testing company took various air permit test measurements. SGS has tested the two fuel sources to the furnace, Tire Durative Fuel Oil (TDFO) and Tire Durative Gas (TDG). SGS has also tested the furnace exhaust gas before and after the scrubbers. All testing has met the requirements for various countries' air permits.

Marketing Plan

The Marketing plan is simple; the outputs of the plant are essentially commodity items. The demand for oil, carbon black and steel are well known industry wide. The Company has two unique advantages in the marketing all three commodity items.

The first advantage is that all three of the Company's products are essentially created from waste tires and thus are considerably less expensive to produce. This critical advantage allows the Company to discount their price to the market while still showing aggressive ROI. The second advantage, our raw material supply chain is virtually unlimited. The feed stocks for the plant to produce these commodities are provided to the Company in “unlimited” quantities at little to no cost. Additional income now, will come by tire haulers dropping off their waste tires to the Company. The major production costs are the shift labor and electricity used by the production line. When the Company processes 1% of the waste tires in USA, we will need an additional 100 plants running at double the capacity of this initial plant.

We intend to take full advantage of the recycling revolution and the “Green Industry”. We all are aware of the current oil imports into the Untied States. However, USA requires far more oil than can currently be produced. So establishing a market for the fuel oil is not required, the market already exists and will absorb all the oil it can. We believe there are large consumers of fuel oil that will buy at market price and our Tire Derived Fuel Oil (TDFO) will have a “green advantage” for our own advertising programs. The fuel is “green”, recycled, and provides our customers the additional “bragging rights” of helping the environment by reducing waste without further depleting the worlds resources. The Fuel oil will be marketed to large scale consumers operating boilers or other large diesel oil consumers. The fuel produced by the system is the equivalent of #2 Diesel Oil.

The goal is to tap into specialty carbon black markets. However, until these markets can be readily identified, the output will be customized for particular carbon black markets. We can also go to existing carbon black chemical companies to blend with their current production. This will provide the Company a ready market to sell to and reduce the cost of carbon black to various chemical companies.

Carbon Black Market to Exhibit 4.8% CAGR from 2024 to 2030

According to the new report published by Grand View research, the global carbon black market size was estimated at USD 22.35 billion in 2023 and is projected to expand at a CAGR of 4.8% from 2024 to 2030

Increasing automotive sales and consequent rise in tire production is expected to drive industry growth over the forecast. The vast majority of carbon black finds use as reinforcement material in vulcanized rubber goods, including over 60 percent in motor vehicle tires alone. Carbon black acts as a reinforcement material for tires and rubber, and possesses electrical conductive properties. Carbon black provides pigmentation, conductivity, and UV protection for a number of coating applications along with toners and printing inks for specific color requirements. Its multiple applications across various end products along with rising economic outlook have significantly enhanced its demand over the years.

Special Blacks Market Sector projected to grow at 10.2% CAGR from 2024 to 2030

According to Grand View research, the global specialty carbon black market size was estimated at 2.74 billion in 2023 and is projected to grow at a CAGR of 10.2% from 2024 to 2030. China's specialty carbon black market is projected to grow at a CAGR of 12.2%. This is attributed to the surging demand for the product as reinforcing agents and other uses.

Operation Plan

The material for the plant is relatively simple. The used tires will be delivered to the plant in 40" container boxes on wheels. The filled containers will be parked at the loading lot for unloading. Once parked, the tractors will disconnect from the containers, and leave it for the Company to empty.

The loading lot will have a continuous conveyor running into a feeding system. The Company is currently scheduled to receive trucks 7 days a week and 24 hours/day. During this time, Company employees, will manually off load trucks to the system. The Company will stage supply chain required for each day’s consumption to allow for 24 hours operation, 7 days per week.

The actual plant is almost fully automated with the exception of unloading. The production only requires a shift Operation Engineer alongside an assistant engineer. The engineers will be able to monitor the entire plant with cameras and other instruments.

Operation Plant Manning

The 0800-1600 shift (Monday-Friday) will normally be comprised of 4 dock workers, 1 warehouse material worker (moving packaged Carbon Black), 1 shift Operating Engineer, and 1 assistant engineer.

The 0000-0800 shift (Monday-Friday) will normally be comprised of , 1 warehouse material worker (moving packaged Carbon Black), 1 shift Operating Engineer, and 1 assistant engineer.

The 0800-1600 shift (Saturday-Sunday) will normally be comprised of, 1 warehouse material worker (moving packaged Carbon Black), 1 shift Operating Engineer, and 1 assistant engineer.

The 0800-1600 shift (Saturday-Sunday) will normally be comprised of, 1 warehouse material worker (moving packaged Carbon Black), 1 shift Operating Engineer, and 1 assistant engineer.

The 1600-2400 shift (Sunday-Saturday) will normally be comprised of , 1 warehouse material worker (moving packaged Carbon Black), 1 shift Operating Engineer, and 1 assistant engineer.

The 0000-0800 shift (Sunday-Saturday) will normally be comprised of , 1 warehouse material worker (moving packaged Carbon Black), 1 shift Operating Engineer, and 1 assistant engineer.

Consultants

Ed and Nancy Drews – Consultants to ARC Waste Tires Inc. in providing strategic analysis for project development and have been involved in the tire recycling industry since the mid 1980's, before any states had legislation on waste tires. They have manufactured tire recycling equipment since 1990 and have acted as consultants on numerous successful civil engineering projects utilizing tire bales. Over the years they have attended and presented at many tire recycling conferences in the United States and Europe. They have followed and studied most of the various tire recycling technologies that have been implemented over the last 25 years and have seen technology improve to increase opportunities for successful tire recycling facilities.

Future Vision

The Company has the capability to expand quickly. The Adelanto location should be large enough to double output production. We are working with our suppliers to acquire additional supply chain North America wide in addition to Central and South America.

The Company can be expanded by:

- Seeking and identifying additional supply chain that acquires tires from retail centers and landfills. These suppliers would have a vested interest in the expansion project due to the eliminating of their land fill costs.

- Developing joint ventures with tire manufacturers to consume their scrap and improve returns for both companies.

- Developing partnerships with major tire manufacturers providing carbon black for their production

- Assist and help 3rd world countries with additional supply chains to oil and carbon black usages.